Patent Pages

by Ray Klingensmith

Reprinted from "INSULATORS - Crown Jewels of the Wire", April 1978, page 14

This month the featured patent is the "elusive Emminger". And

elusive this insulator certainly is. It was patented by David R. P. Emminger on

February 20th, 1872, being issued patent number 123,878. The patent reads "

The nature of my invention consists in so constructing my improved 'insulator'

that dust and dirt are prevented from accumulating upon its outer surface. Also

in reducing the points of contact of the conducting wire with the insulator, in

a great degree, by a peculiar method of construction of said insulator."

"Upon its outer surface, a proper distance from the upper rounded end, four

rhombus or lozenge-shaped projections aaaa, are formed. These projections have

circular or rounded notches formed in their outer edges a proper distance from

their terminations. They are intended to receive and retain in place the

binding wire that secures the conducting wire to the insulator."

And a "peculiar" design Emminger did in fact produce. This must

have been a very good design, as all Emmingers known to me were in fact free of

any dust and dirt deposits. All were very clean.

And how many Emmingers are

there in collections? There are a definite seven, and possibly two others which

have not definitely been confirmed. Of the seven positively existing, only one

is "mint", the rest having varying degrees of damage. Although these

are now widely scattered across the country, it seems the original location for

their appearance is Pennsylvania. The one mint one that turned up several years

ago in Ohio, was purchased from an individual from an unknown location. (ref.

Great Lakes Show, 1975. The person who brought this mint Emminger was from Ohio. But the person he acquired it from

could have been from elsewhere.)

Another interesting feature of this patent,

other than the four projections, is the type of pin to be used. Although this

insulator has been found with only a standard threaded pinhole, it has an unusual "special threadless" pinhole in the patent drawings. (See my

drawings below for this unusual feature.) The insulator was to have a smooth

threadless pinhole. At the lower portion of the pinhole or recess, two knobs

were formed opposite each other. A special pin was made with two parallel

grooves positioned in a manner to receive the knobs within the insulator. The

pin was formed so that the insulator could be aligned on the pin (knobs on

insulator with grooves on pin), then pressed downward and turned so as to lock

it in position. The insulator could not rise, as the knobs were under the

shoulder. (See drawing below.) Although no one has found an Emminger with this

special feature, to my knowledge, it certainly is interesting and gives us

something to look for. Imagine a threadless Emminger!

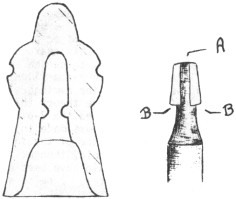

Drawings showing interior "knobs" and unusual grooved pin. The

knobs fit into the grooves (A) and were turned under the shoulder (B). |

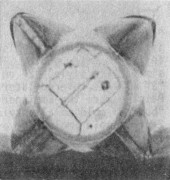

Top view photo showing "creases" design in top of pinhole very similar to

those found in Paisleys. |

As with many other "patents", the main feature on the insulator is

the same, and another aspect of the insulator is different than that of the

patent drawings. In this case it is the type of pin to be used. There are

several explanations as to why all Emmingers found so far are all threaded.

First: A small amount of the "special threadless" were possibly

manufactured, used, and found unsatisfactory. Second: This early patent date was

just after the use of the threaded pin was becoming popular, and Emminger,

between the time he applied for the patent (most likely mid 1871), and the time

of manufacturing, realized the advantage of using a threaded pin, and had it

manufactured that way. Third: The knobs in the pinhole would require special

manufacturing moulds and skills, and was therefore abandoned. Fourth: When

Emminger contracted with a manufacturer to make them, the manufacturer suggested

the advantages of a threaded interior, and they were made that way.

Who made the

Emminger? We really have very little to go on when it comes to the manufacturer.

Let's examine a few possibilities. Some may feel the base embossing suggests a

Boston, Massachusetts, area manufacturer. My opinion on this, is that it wasn't. First, because of

the early Emminger date (1872). Boston Bottle Works was in business from

1872-1877. American Ins. Co., National, Standard and others were much later. So

the only likely possibility would be Boston Bottle Works. Oakman was more than

likely using his own slotted threadless pinhole in early 1872, and his

segmented-threads in late 1872 and the years to follow. Only one style of a

"Boston" has been found with full threading. For those reasons the

Boston area is unlikely in my opinion, but it still is a possibility.

Another

possibility is S.T. Paisley. And this possibility I seem to favor for some

"instinctive feeling". Paisley was listed as a mould maker in Beaver

Falls, Pennsylvania. There once was a Beaver Glass Co., and a Valley Glass Co.

in Beaver Falls, Pennsylvania. I'm not sure of the exact manufacturing dates. We

know Paisley was making early (Appearance of glass and styles made seem to be ca. 1870's.) threaded insulators for someone. (Paisley

could also have made the CD 733.2 with M on the

dome.) Every embossed Paisley, unembossed 132.2, and other "Paisley styles"

that I've ever seen had one thing in common: a "crease" in the top of

the pinhole in various shapes--

These must have been caused by a unique

characteristic in the mandrels or plungers Paisley used. (EC&M's are the

only other items with this characteristic.) The Emminger also has this unusual

"crease", as can be seen in the top view photo. The CD 132.2 in my

collection has a slightly similar (in style) "2" on the dome. (The

oddity of the Emmingers' "2" will be covered later.) The only soft

spot in the theory that Paisley made the Emminger is the fact that Paisley used

the 3-piece "button" mold on all styles I know of. The Emminger was

made in a 2-piece mold (mold line over dome). The peculiar shape of the

insulator could explain the reason for using a 2-piece mold, though.

The third,

and another likely manufacturer, could have been one of several glass works of

the time in the general area. I believe Lancaster Glass Wks. was still in

business at that time. This is a likely candidate, as Emminger didn't live too

far from Lancaster. There were several glass houses in Philadelphia and

Pittsburgh, Pennsylvania, and New Jersey that could also have made them. I feel

it wasn't an item made by either Hemingray or Brookfield.

As mentioned above,

there is a special characteristic in the "2" embossed on the Emminger.

It has a long curved tail (See base photo and rubbing of embossing.). This is

another feature which adds to the "class" of this Insulator. If anyone

has a CD 132.2 or any other insulator with the fancy "tailed 2",

please send a rubbing of it, as it would help confirm the manufacturer.

In this

day and age of space travel, supersonic speed, pyramid power, "Close

Encounters", UFO's and the unknown, David Emminger may have had a design

with much more meaning than just a technical Improvement. It does have a

peculiar pyramid shape. It's an item I've been chasing for a long time. It just

has something about it. Many collectors and non-collectors alike say one thing

in common: "It looks like it's ready to take off." I guarantee you one

thing, If I'm ever fortunate enough to own one of these jewels, I probably won't

hit the ground for a week! And to all the people who are fortunate enough to own

an Emminger -- We all envy you.

Anyone have anything to add? If so, contact me at

709 Rt. 322, East Orwell, Ohio 44034. Next month: the 1874 Brooke's Patent.

Special Note: A real big thanks to Mike Johnson for his trouble and time

involved in bringing this jewel to a "photo session".

|